Insulation Panels for Boilers and Heaters, Soluble Fiber Board

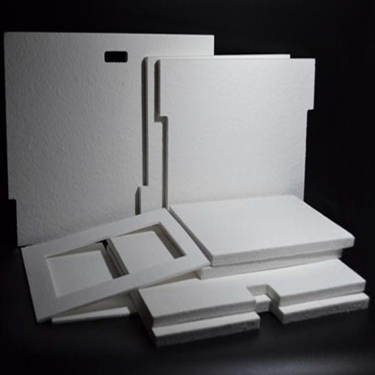

Insulation Panels are designed for insulating boilers, water heaters, heaters or combustion chambers, and any heating units (heating elements) of heat shields or gaskets.

Insulation Panels are made with soluble fiber board or improved ceramic fiber board for increased mechanical strength and reduced impurities. Some other advantages: high classification temperature (2190F, 2300F, 2600F), environmentally/health friendly, custom shapes, precise shapes with

±1 mm tolerance control, thinnest board at 3mm, etc. We have many other related products to offer: 6mm soluble fiber blanket, ceramic fiber paper, and custom shaped insulation products for boilers' and heaters' insulation needs.

Bio Soluble Fiber Blanket Datasheet

Bio Soluble Fiber Blanket Datasheet